-

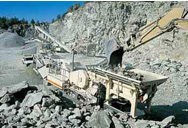

Мобильная дробилка

- Каменная дробилка на прокат Дарлингтон

- Лаборатория Дробилки Австралия

- Для подземных работ Conevor Установка

- Зенит конусная дробилка головка и ручка

- maufactuere каменная дробилка завод в Мумбаи

- дробления в цементной промышленно

- модель гидравлической дробилки

- горное оборудование для добычи золота

- завод по переработке гипса в пакистане

- оборудование для добыча хромитовых

- цены на дробилки ксд

- добыча мобильные дробилки YouTube

- флотационных машин в танзании

- простые машины для измельчения деятельности

- дробилка для ящиков канистр и ведер

- введение щековая дробилка производства

- каменная дробильная установка тонна в час

- Гильотина для производства рваного колотого блока, кирпича

- Нэг метр тутамд туузан дамжуулагчийн зардал

- щебень продажа покупка

<В процессе известняка дробилки

Щебень - продажа, покупка, цены ... - MM

Щебень - лучшие предложения в Латвии. Предлагаем Вам ознакомиться с объявлениями раздела. Новые объявления на сайте MM.lv

Read More

SS.LV Стройматериалы - Щебень, Цены ...

Доставка щебня (все фракции) и др. cыпучих материалов на самосвалах Scania/mercedes-Benz до Рига, Зиепниеккалнс Rīgas raj.

Read More

щебень - OLX.ua

Щебень 5.20.40.70‼️Песок сеяный, камень, бетон, отсев, чернозем‼️глина 439 грн. Одесса, Киевский - 30 июля 2024 г.

Read More

Купить щебень с доставкой: цена за 1 м3 ...

Компания МосОптНеруд: Щебень - купить по низким ценам, доставка щебня по Москве от 1 м3 (куба) в день заказа, собственный автотранспорт, прямые поставки

Read More

SS.COM Стройматериалы - Щебень, Цены ...

32 行 Доставка щебня (все фракции)и др. cыпучих материалов на самосвалах

Read More

Купить щебень с доставкой в Москве ...

Продажа щебня с доставкой по Москве и Московской области. Доставим от 3м3. Работаем 24/7. Сертификаты на все фракции и виды щебня. Собственный

Read More

Щебень. Цены, покупка, продажа

Доска объявлений по теме Щебень. Цены, покупка и продажа, спрос и предложение. Широкий выбор товаров и услуг на сайте бесплатных объявлений pdo .

Read More

Торговая площадка сообщества Steam ...

Покупайте и продавайте предметы из Counter-Strike 2 на Торговой площадке за средства кошелька Steam.

Read More

Щебень в Минске по выгодной цене ...

Завод ЖБИ изделий. Минск. +375 показать номер. Щебень известняковый (доломитовый) фр. 60-120. от 10 бел. руб/шт. в наличии. Опт. 22.07.24. Обширный

Read More

Купить щебень в Новосибирске с ...

В компании «Доставка-Щебень» вы можете купить гранитный и гравийный щебень любой фракции по самой выгодной цене! Сопровождаем сделку от оформления

Read More

Купить щебень, песок в Краснодаре ...

Продажа щебня в ... покупка и доставка инертных строительных материалов ... Например, гранитный щебень с фракцией в 40-70мм будет стоить всего 540 рублей, а с фракцией 5-10мм – уже 860 рублей.

Read More

щебень продажа покупка

Щебень ГРАНИТНЫЙ с доставкой, песок ПРОДАЖА. 2020-6-22 щебень дешево, щебень цена за м3, щебень с доставкой цена, продажа щебень цена, сколько стоит куб Продажа Покупка щебня с доставкой в Петербурге и области собственным ...

Read More

SS.LV Стройматериалы - Щебень, Цены ...

Объявления. Стройматериалы - Щебень, Цены, торговля, Фото, Kартинки. Доставка щебня (все фракции)и др. cыпучих материалов на самосвалах Scania/mercedes-Benz до 1

Read More

Продажа щебня с доставкой. Щебень ...

Мы занимаемся продажей щебня с доставкой в Самару, Ульяновск, Саратов, Волгоград, Оренбург, Казань. Если вы хотите купить щебень – звоните! />

Read More

щебень производители России и СНГ ...

щебень покупка / продажа 24.05.17 Щебень (фр.20-40) от компании «ГК СЛОН» 24.05.17 Щебень (фр.10-20) от компании «ГК СЛОН» 24.04.16 Пгс, щебень, гравий, песок, торф, труба нкт.

Read More

Щебень оптом. Продажа гранитного щебня ...

Список компаний и дилеров поставляющих щебень во все регионы Украины. Цены на щебень от производителя в 2022 году. ... Оптовая продажа гранитного щебня в ...

Read More

Щебень. Цены, покупка, продажа

Доска объявлений по теме Щебень. Цены, покупка и продажа, спрос и предложение. Широкий выбор товаров и услуг на сайте бесплатных объявлений pdo .

Read More

SS.COM Стройматериалы - Щебень, Цены ...

Oбслуживаем Рига и в окрестностях 100 км Щебень( Бетон) (20-40)(40-70) 9, 50 eur/m3. Щ Рижский р-он, Стопиньский округ

Read More

Купить щебень в Новосибирске с ...

В компании Доставка-Щебень вы можете купить щебень в Новосибирске с бесплатной доставкой, продажа по самой выгодной цене! Звоните по тел.: +7(383) 239-58-52.

Read More

ЗАО «Австрофор» - покупка и продажа ...

ЗАО «Австрофор» занимается покупкой и продажей круглого леса, реализацией пиломатериалов. Опыт работы более 30 лет. Выгодные цены. Доставка своим транспортом.

Read More

Продажа щебня с доставкой. Щебень ...

Мы занимаемся продажей щебня с доставкой в Самару, Ульяновск, Саратов, Волгоград, Оренбург, Казань. Если вы хотите купить щебень – звоните! />

Read More

Песок Щебень в Солигорске с доставкой ...

Песок, Щебень в Соилигорске и Солигорском раене по оптимальной цене. Любой объем от 10 тонн и выше с выгрузкой на любой объект. ... а также продажа песка, ...

Read More

Купить щебень с доставкой в Минске ...

Компания Вторичный щебень уже более 6 лет на рынке! ... продажа щебня оптом различных фракций; переработка древесных отходов в экологическое топливо – щепу.

Read More

Купить щебень во Владивостоке с ...

Продажа щебня различных фракций - смесь, отсев, скала, дроблёный бетон, асфальтовая крошка. ... Мы продаем щебень для строительных работ оптом и в розницу, ...

Read More

Купить щебень — Владивосток Цены на ...

Завод производит щебень различных фракций: от 5-20 мм до 40-70 мм. Цена за тонну при покупке щебня оптом составляет около 1600 рублей. Покупка щебня в мешках и расчет цены за куб

Read More

Купить щебень в Минске с доставкой - Stroyka24

Продажа гранитного и гравийного щебня в Минске и минской области - Stroyka24.by ☎ +375 (44) 5555-727. Доставка самосвалами, фасовка в мешки.

Read More

Чернозём - продажа, покупка, цены ...

Pārdodam sijātu un nesijātu melnzemi . Pārdodam sijātu un nesijātu melnzemi , kā arī citus dažādus būvmateriālus - smilts , šķemba un tā tālāk Ir pieejamas visdažādākās šķembu frakcijas, kā arī pārstrādās kieģelis, pārstrādāts betons un dažādi citi materiāli, kas var aizstāt šķembas un realizēt Jūsu intereses.

Read More

Щебень: еврофракции щебня

щебень прибрежное артемовское сибирцево. К примеру, основание любой магистрали должно быть сделано из гранитного щебня, но в Брянске нет ни одной дороги, изготовленной по этой основном из-за нехватки средств ...

Read More

щебень - Купить готовый бизнес в ...

51 объявление о продаже готового и действующего бизнеса в Ульяновске. На Авито вы можете недорого купить готовое ООО, действующий бизнес для покупки, например салон красоты, кафе, производство и другие предприятия, а ...

Read More

Щебень: покупка щебня и гравия

продажа и покупка ... Известковый щебень прочность от 300 до 800 фракции 5-20, 20-40, 40-70, 80-120 ГОСТ 8267-93. доставка по гу Московской области. поставка в бой регион Европейской части РФ.

Read More

Щебень в Минске по выгодной цене ...

Щебень продажа в Минске - сравните прайс-листы, характеристики, фото и выберите лучшее предложение на Пульсе цен

Read More

Топкинский щебень - Карьеры России

2023.12.8 Продажа месторождений. Продажа месторождений; Покупка ... ЩЕБЕНЬ фракции: 5-20, 20-40, 40-70 , 80-120 марка по дробимости от М600 до М1200 морозостойкость не ниже f150

Read More

Доставка щебня в Новосибирске с ...

Продажа и быстрая доставка щебня по Новосибирску и Новосибирской области по самым ... Купить гранитный щебень с доставкой с карьера Борок можно в компании Куб по максимально выгодной ...

Read More

Карьер Пушкарка - Карьеры России

2024.2.16 Покупка ... Производство и оптовая продажа напрямую с карьера Пушкарка Наро-Фоминский р-он Щебень известняковый 5/20 — 1150 руб/т. Щебень известняковый 20/40 — 1050 руб/т.

Read More

щебень продажа покупка

щебень производители России и СНГ. щебень ... щебень покупка / продажа 24.05.17 Щебень (фр.20-40) от компании «ГК СЛОН» 24.05.17 Щебень (фр.10-20) от компании «ГК СЛОН» 24.04.16 Пгс, щебень, гравий, Детали

Read More

Песок - продажа, покупка, цены ...

Песок подсыпной для поднятия уровня участков(Цена от 5.50 евро). Грунт земляной для поднятия уровня участков. Гальку дренажную и декоротивную всех фракций. Щебень доломитный всех фракций....

Read More

Купить песок и щебень с доставкой в ...

Проект «Щебень России» создан с целью аккумулирования актуальной информации об отечественном рынке нерудных материалов и всех его участников, ... покупка или продажа щебня в Москве.

Read More

Карьер Саянский щебень - Карьеры России

2023.4.29 Продажа месторождений. Продажа месторождений; Покупка месторождений; Поиск инвестора; Аудит и проверка карьера; Нерудные материалы. Каталог компаний по продаже и поставке нерудных ...

Read More

Щебень: методика определения ...

продажа и покупка ... щебень и цемент по рыночной цене Монополии в добыче щебня - еще одного важного компонента бетона Хорошо мой журнал сегодня читают: ...

Read More

песок щебень доставка - Купить ...

51 объявление о продаже франшиз в Рассказово. На Авито вы можете недорого купить франшизу, например салон красоты, кафе, магазин или другой бизнес по франшизе. Выбирайте среди предложений собственников о продаже ...

Read More